DMLS (Direct Metal laser Solidification) is the widely used technology or method in the additive manufacturing process chain. DMLS is a fast, flexible, and cost-effective solution to produce end parts or tools in metals. DMLS components mechanical properties are far superior to cast properties and in the range of wrought properties, directly competing or little closer to forged components.

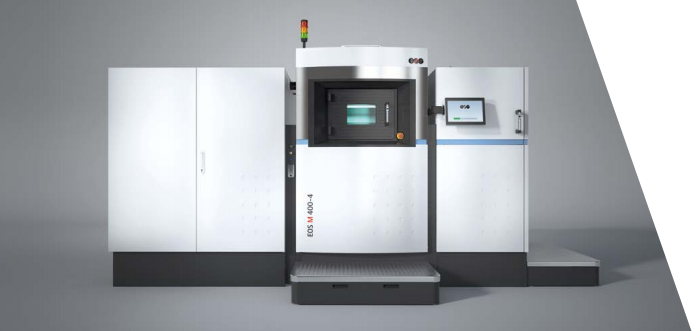

EOS M 400-4

The Ultra-Fast Quad-Laser Additive Manufacturing System for High-Quality Metal Parts.

Materials

EOS Aluminium AlSi10Mg, EOS Nickel Alloy IN718, EOS Nickel Alloy HX, EOS MaragingSteel MS1, EOS StainlessSteel 316L,

EOS Titanium Ti64, EOS Titanium TiCP Grade 2

Building volume

400 x 400 x 400 mm (15.8 x 15.8 x 15.8 in) (height incl. build plate)

Laser type

Yb-fibre laser; 4 x 400 W

Precision optics

4 F-theta-lenses; 4 high-speed scanners

Scanning speed

up to 7.0 m/s (23 ft/s)

Focus diameter

approx. 100 μm (0.004 in)

Power supply

3 x 50 A

Power consumption

max. 45 kW / typical 22 kW

Inert gas supply

7,000 hPa; 20 m3/h (102 psi; 706 ft3/h)

Dimensions (W x D x H)

4,181 x 1,613 x 2,355 mm (164.6 x 63.5 x 92.7 in)

Recommended installation space

min. 6.5 x 6 x 3.3 m (256 x 236 x 130 in)

Weight approx

. 4,835 kg (10,659 lb)

EOS M 400

The Additive Manufacturing System for Industrial Production of High-Quality Large Metal Parts

Materials

EOS Aluminium AlSi10Mg, EOS MaragingSteel MS1, EOS NickelAlloy IN718, EOS Titanium Ti64, EOS Titanium Ti64ELI

Building volume

400 x 400 x 400 mm (15.8 x 15.8 x 15.8 in) (height incl. build plate)

Laser type

Yb-fibre laser; 1,000 W

Precision optics

F-theta-lens

Scanning speed

up to 7.0 m/s (23 ft/s)

Focus diameter approx

. 90 μm (0.0035 in)

Power supply

50 A

Power consumption

max. 20,2 kW / typical 16,2 kW

Inert gas supply

7,000 hPa; 20 m3/h (102 psi; 706 ft3/h)

Dimensions (W x D x H)

4,181 x 1,613 x 2,355 mm (164.6 x 63.5 x 92.7 in)

Recommended installation

space min. 6.5 x 6 x 3.3 m (256 x 236 x 130 in)

Weight approx.

4,635 kg (10,218 lb)

EOS M 300 Series

Digital Additive Manufacturing

for the Industrial Production of High-Quality Metal Parts Designed for industrial applications, the EOS M 300 Series offers multiple configuration options combined with safety and security features enabling digital Additive Manufacturing. The platform offers the flexiblity to choose the degree of automation that best suits your needs for an optimized workflow as well as the option to easily ramp-up as demand increases.

Materials

EOS Aluminium AlSi10Mg, EOS MaragingSteel MS1, EOS NickelAlloy IN718, EOS Titanium Ti64

300 x 300 x 400mm (11.8 x 11.8 x 15.8 in)

Laser type

Yb-fiber laser; 4 x 400 W

Precision optics

4 F-theta-lenses; 4 high-speed scanners

Scanning speed

up to 7.0 m/s (23 ft./s)

Focus diameter approx.

100 μm (0.004 in)

Power supply

3 x 80 A

Power consumption max.

36 kW / typical 26 kW

Inert gas supply

7,000 hPa; 15 m3/h (102 psi; 530 ft3/h)

EOS M 290

DMLS quality is the benchmark in metal additive manufacturing With a building volume of 250 x 250 x 325 mm and 400 W laser, the EOS M 290 allows a fast, flexible and cost effective production of metal parts directly from CAD data.

Materials

EOS Aluminium AlSi10Mg, EOS CobaltChrome MP1, EOS MaragingSteel MS1, EOS NickelAlloy HX, EOS NickelAlloy IN625, EOS NickelAlloy IN718, EOS StainlessSteel CX, EOS StainlessSteel PH1, EOS StainlessSteel 17-4PH, EOS StainlessSteel 316L, EOS Titanium Ti64, EOS Titanium Ti64ELI, EOS Titanium TiCP Grade 2

250 x 250 x 325 mm (9.85 x 9.85 x 12.8 in) (height incl. build plate)

Laser type

Yb fibre laser; 400 W

Precision optics

F-theta lens; high-speed scanner

Scanning speed

up to 7.0 m/s (23 ft./sec)

Focus diameter

100 μm (0.004 in)

Power supply

32 A / 400 V

Power consumption

max. 8,5 kW/ average 2,4 kW/with platform heating up to 3,2 kW

Inert gas supply

7,000 hPa; 20 m3/h (102 psi; 706 ft3/h)

Dimensions (W x D x H)

2,500 x 1,300 x 2,190 mm (98.4 x 51.2 x 86.2 in)

Recommended installation space

min. 4,800 x 3,600 x 2,900 mm (189 x 142 x 114 in)

Weight approx.

1,250 kg (2,756 lb)

EOS M 100

Additive manufacturing system for the fast and efficient production of delicate metal parts

Materials

EOS CobaltChrome SP2 (CE-certified, CE 0537), EOS StainlessSteel 316L, EOS Titanium Ti64, EOS Tungsten W1

Building volume

Ø 100 x 95 mm (Ø 3.9 x 3.7 in)(height incl. build plate)

Laser type

Yb fibre laser; 200 W

Precision optics

F-theta lens; high-speed scanner

Scanning speed

up to 7.0 m/s (23 ft./sec)

Focus diameter

40 μm

Power supply

200 – 240 V

Power consumption

max. 1.7 kW / average 0.60 kW

Inert gas supply

max. 4,000 hPa, 50 l/min

Inert gas consumption

for flooding: up to 600 l / during building: up to 2,5 l/min

Dimensions (W x D x H)

800 x 950 x 2.250 mm (31 x 37 x 89 in)

Recommended installation space

min. 1.00 x 3.00 x 2.5 m (3 x 10 x 8 ft)

Weight

580 kg